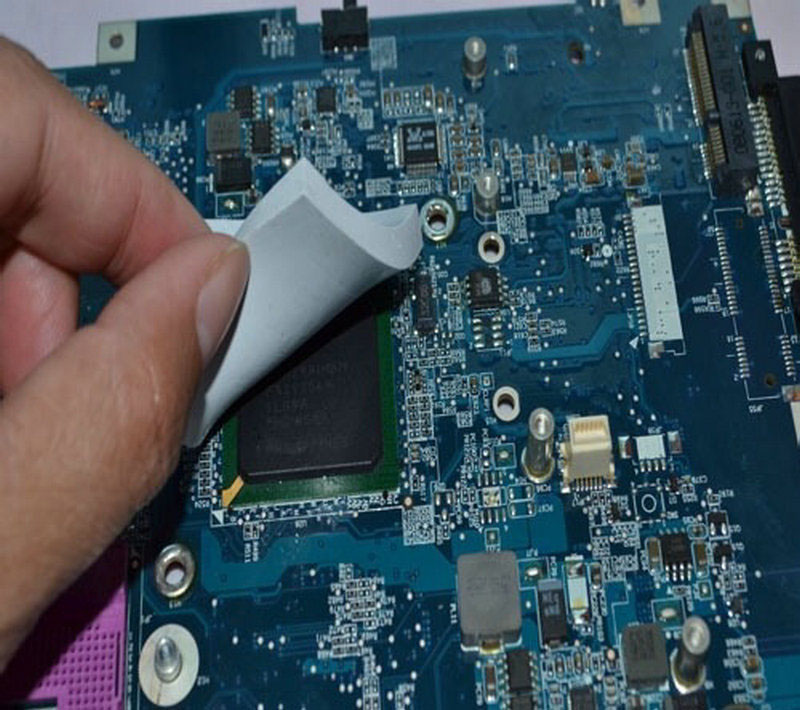

The thermal pad is used to fill the air gap between the heating device and the radiator or metal base. Their flexible and elastic properties make it possible to cover very uneven surfaces. Heat is transferred from the separator or the entire printed circuit board to the metal case or diffusion plate, thereby increasing the efficiency and service life of the heated electronic components.

Product characteristics of thermal conductive silicone sheet:

Good thermal conductivity: 3W/MK; Self-adhesive tape without additional surface adhesive; High compressibility, soft and elastic, suitable for low pressure application environment; Available in a variety of thicknesses.

The six major industries in which heat-conducting thermal pads are mainly used include light-emitting diode industry, automotive electronics industry, plasma/light-emitting diode TV industry, home appliances industry, power supply industry and communication industry.

First, the use of light-emitting diode industry:

1. Thermal conductive silicone sheet is used between aluminum substrate and radiator.

2. Thermal conductive silicone sheet is used between aluminum substrate and shell.

Two, automotive electronics industry application:

1. Thermal conductive silicone sheet can be used in automotive electronics industry applications (such as xenon lamp ballast, sound system, vehicle products, etc.).

Three, plasma display/LED TV application:

1. Heat conduction between power amplifier integrated circuit, image integrated circuit and radiator (shell).

Four. Home Appliance Industry:

1. Microwave oven/air conditioning (between fan motor power integrated circuit and shell)/ induction oven (between thermistor and radiator) can be used to heat conduction silicone sheet.

Five. Power Supply industry:

1. Conductive silicone sheet in metal oxide semiconductor tube, transformer (or capacitor/power factor correction inductor) and heat sink or shell conduction heat.

Six. Communication Industry:

1. Heat conduction and heat dissipation between the motherboard integrated circuit and the radiator or shell.

2. Heat conduction and heat dissipation between DC-DC integrated circuit and set-top box shell.

Post time: Jan-09-2023