When choosing the right thermal silicone pad, there are several factors to consider to ensure optimal performance and reliability. These pads are often used in electronic devices to transfer heat away from sensitive components, and choosing the correct pad is critical to the overall functionality of the device.

First, it is important to consider the thermal conductivity of silicone pads. This is a measure of how efficiently the pad transfers heat, usually measured in Watts per meter Kelvin (W/mK). The higher the thermal conductivity, the better the heat transfer effect, so choosing a pad with a high thermal conductivity is very important to ensure efficient heat dissipation.

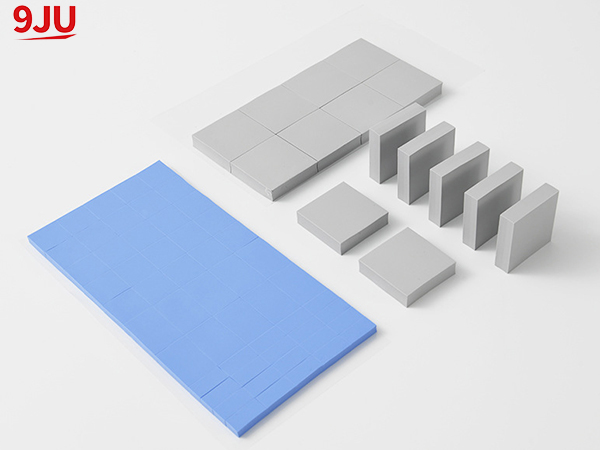

In addition to thermal conductivity, the thickness of the silicone pad is also a key factor to consider. Thicker pads can provide better thermal performance, but they can also create greater thermal resistance if not properly matched to a specific application. It is important to balance the thickness of the pad with the specific requirements of the device to achieve the best results.

In addition, the mechanical properties of silicone pads cannot be ignored. The pad should be soft enough to conform to the surface it contacts, ensuring good thermal contact, but it should also be strong enough to maintain its integrity over time. Additionally, the pad should be able to withstand the device’s operating temperature and environmental conditions without reducing or losing its thermal conductivity.

Another important consideration, especially in electronic applications, is the dielectric strength of the silicone pad. It is critical to ensure that the pads can provide electrical insulation where necessary to prevent any short circuits or electrical interference.

Finally, the size and shape of the silicone pad should be chosen to fit the specific components and layout of the device. Custom shapes and sizes may be required to ensure proper coverage and contact with heating components.

In short, choosing a suitable thermally conductive silicone pad is crucial for the efficient and reliable operation of electronic equipment. By considering factors such as thermal conductivity, thickness, mechanical properties, dielectric strength and size, manufacturers and engineers can ensure that the selected pads meet the specific requirements of the application, ultimately increasing the performance and longevity of the device.

Post time: Apr-15-2024