Professional smart manufacturer of thermal conductive materials

10+ Years Manufacturing Experience

- tiger.lei@jojun.net

- +86 512-50132776

JOJUN-8350 Series Thermal Paste

★ Typical Properties of JOJUN-8350 Series Thermal Paste

|

Thermal Conductive Paste |

|||

|

Property |

Unit |

Product Series |

Test Method |

|

JOJUN-8350 |

|||

|

Color |

|

Gray |

Visual |

|

Density |

g/cc |

3.1 |

ASTM D792 |

|

Extrusion Speed @30cc, 90psi |

g/min |

10-90 |

|

|

Application Temperature |

℃ |

-50~+200 |

|

|

Flammability Class |

|

V0 |

UL94 |

|

Thermal Conductivity |

W/m-K |

3.5 |

ASTM D5470 |

|

Breakdown Voltage |

KV/mm |

>5 |

ASTM D149 |

|

Volume Resistivity |

ohm-cm |

10^13 |

ASTM D257 |

|

Dielectric Constant |

1MHz |

7 |

ASTM D150 |

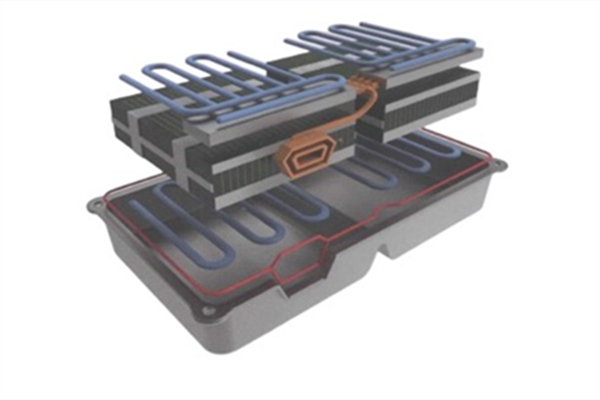

★ Application

LED chip

Communication equipment,

Mobile phone CPU,

Memory module,

IGBT

Power modules,

Power semiconductor field.

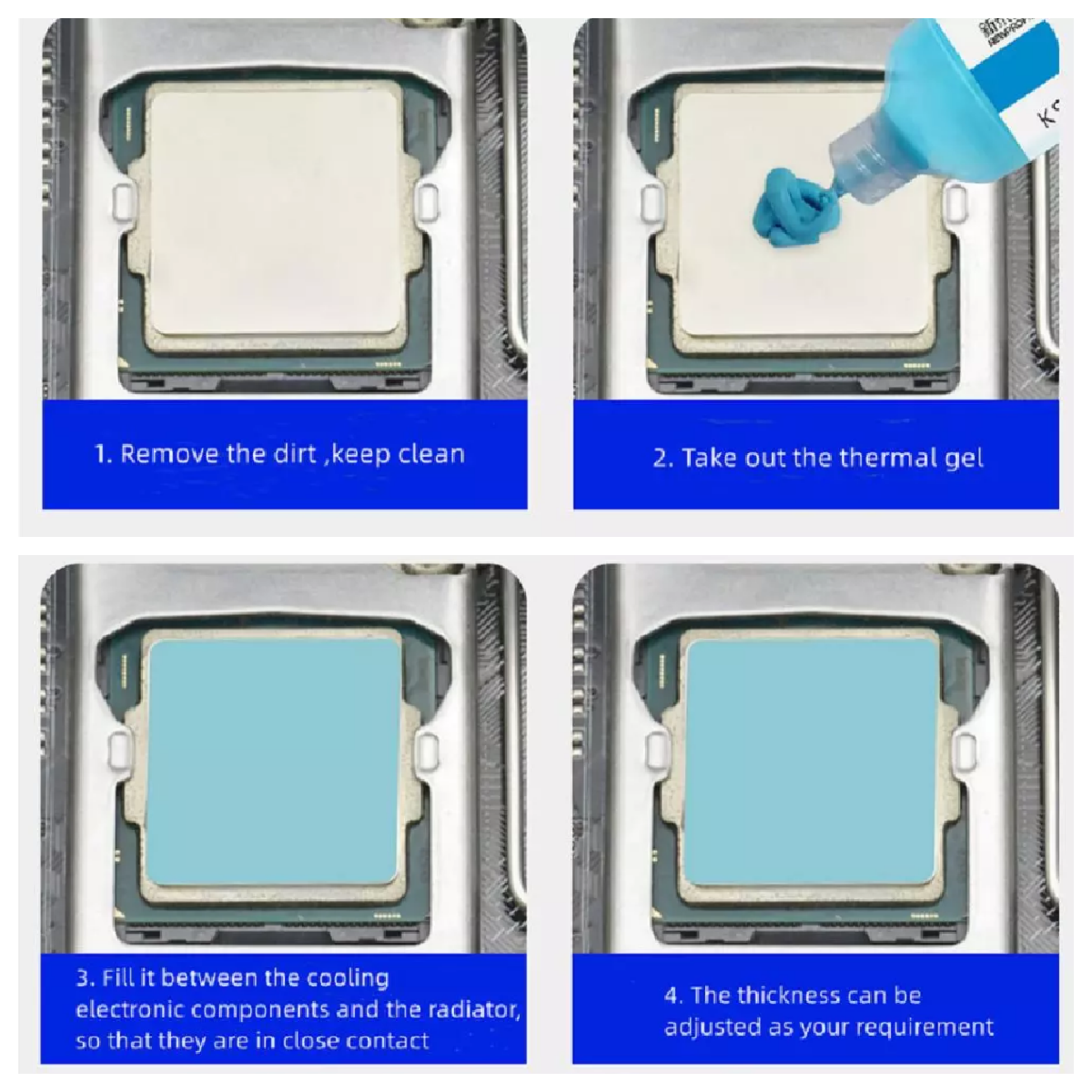

★ Usage

★ Production Process

Mix Stir

Extrusion

Thermal Pad Production Line

Crop

Package

Outgoing Goods

★R&D Center

Voltage Breakdown Tester

Thermal Conductivity Tester

Kneader

Laboratory

★Features And Benefits

Compared with thermal pad, thermal paste is softer and has better surface affinity. It can be compressed to a very low thickness, which significantly improves the heat transfer efficiency, and can be compressed to 0.1mm at the lowest. At this time, the thermal resistance can range from 0.08℃·in2/W to 0.3 ℃·in2/W, which can reach the performance of part of the silicone grease. In addition, thermal paste has almost no hardness, after the use of the equipment will not produce internal stress.

Introducing JOJUN-8350 Series Thermal Paste, the latest innovation in thermal management technology! Say goodbye to traditional silicone grease and enjoy the ease of use and superior performance of our thermal pastes.

Unlike silicone greases, which are difficult to apply and can only be used for specific applications, our thermal pastes are versatile and easy to use. It can be used for screen printing or stencil printing, and can be directly brushed on the surface, making it a breeze to use. Plus, it's more environmentally friendly than traditional silicone greases, making it an excellent choice for those concerned about their environmental impact.

One of the greatest benefits of our thermal paste is its ability to be molded into any desired shape. This makes it ideal for use on uneven PCB boards and irregular devices such as batteries and component corner parts. This ensures good contact between the surfaces, which is essential for optimal heat transfer and thermal management.

JOJUN-8350 series thermal paste uses high thermal conductivity mud, which has excellent heat transfer performance. It enables efficient heat dissipation, prevents heat buildup, and minimizes the risk of damaging components due to overheating.

JOJUN-8350 series thermal paste is also very durable, making it ideal for busy work environments. It can withstand high temperatures and wear, ensuring long-lasting performance and protection for your electronics.

Overall, JOJUN-8350 series thermal paste is a must-have for anyone looking to improve thermal management of their devices. Its ease of use, versatility and outstanding performance make it the first choice of professionals and amateurs alike. Try it now and discover the benefits of our innovative thermal management technology!

★ Certificates

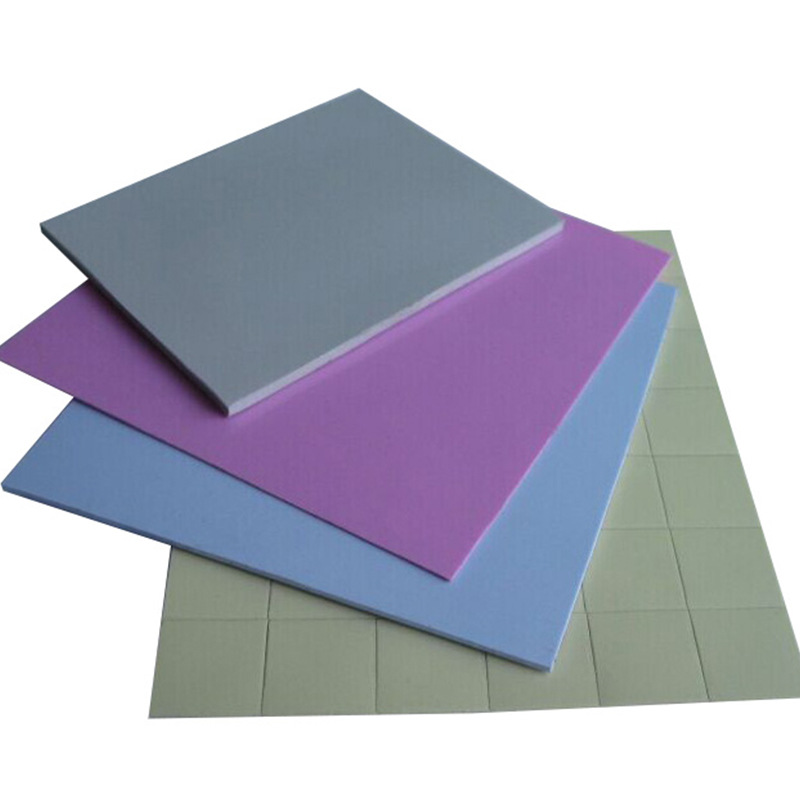

Features of Thermal Products

-

Features of Thermal Pad

1. Good thermal conductivity: 1-15 W/m-K.

2. Low hardness: The hardness ranges from Shoer00 10~80.

3. Electrically insulating.

4. Easy to assembly. -

Features of Thermal Paste

1. Two-part dispensable gap filler, liquid adhesive.

2. Thermal conductivity: 1.2 ~ 4.0 W/m.K.

3. High voltage insulation, high compression, good temperature resistance.

4. Compression application, can achieve automated operations. -

Features of Thermal Grease

1. Low oil separation (towards 0).

2. Long-lasting type, good reliability.

3. Strong weather resistance (high and low temperature resistance -40~150 ℃).

4. Moisture resistance, ozone resistance, aging resistance.